Hartmetall

Hart wie Diamant. Von Krupp erstmals 1926 unter dem Markennamen „Widia“ eingeführt, ist der Name dieses Werkstoffs Programm.

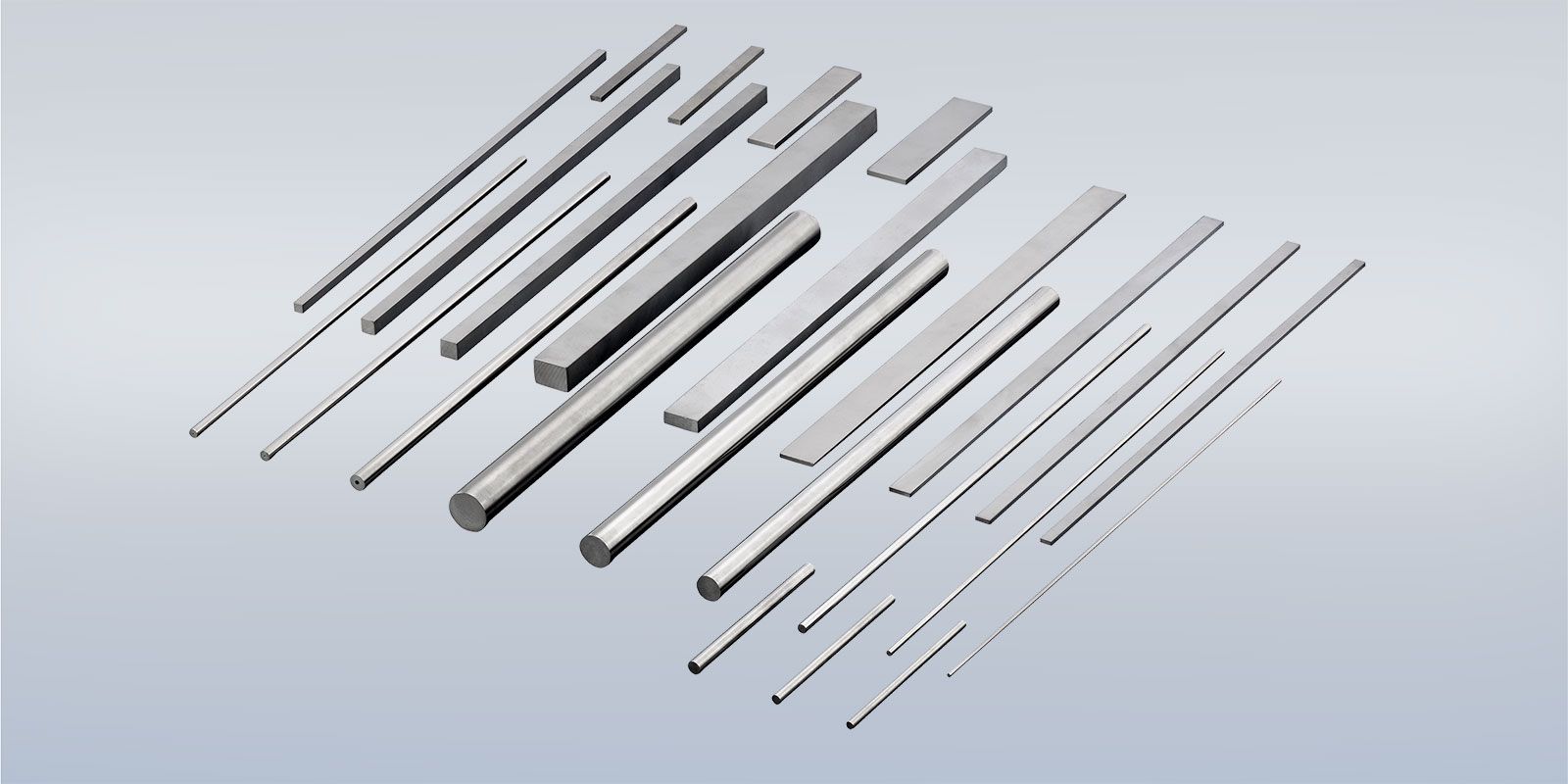

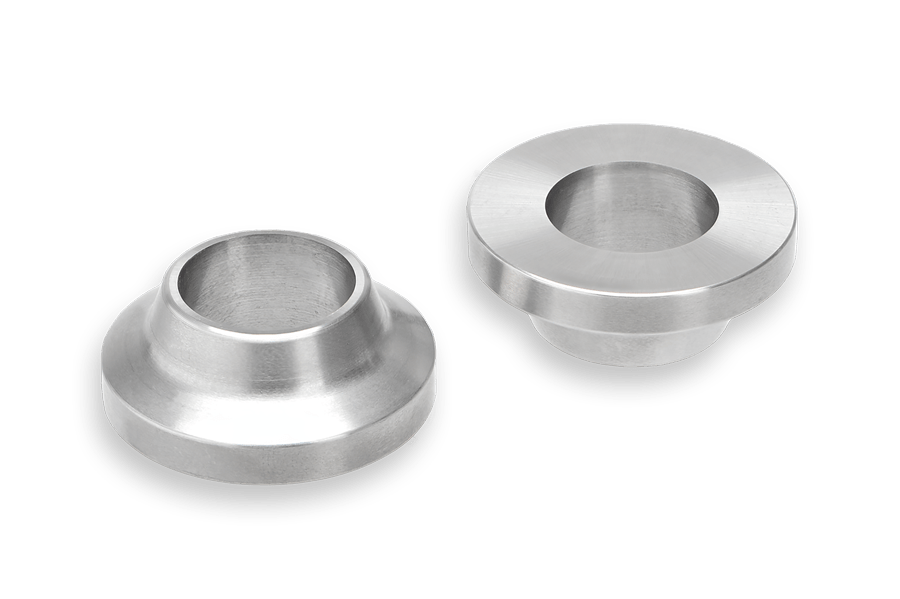

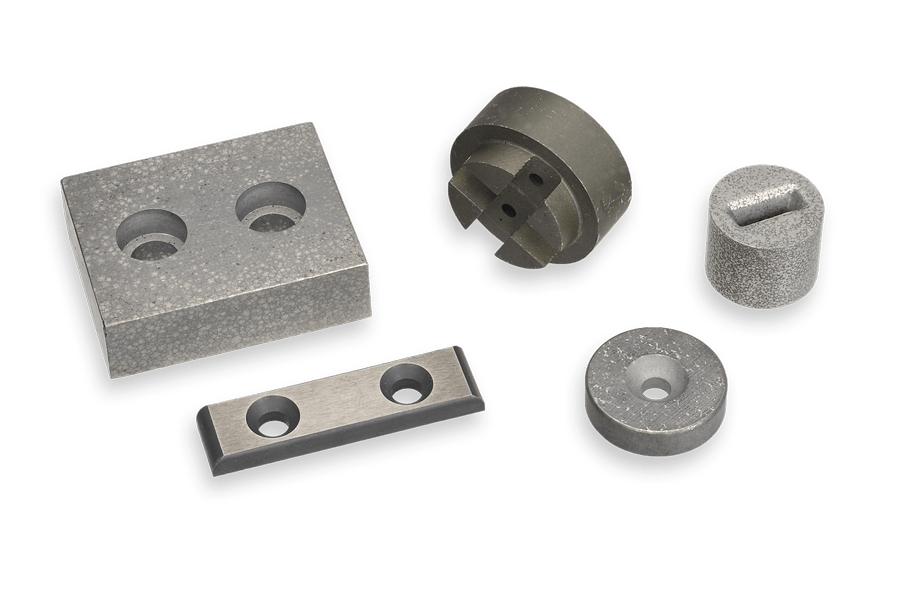

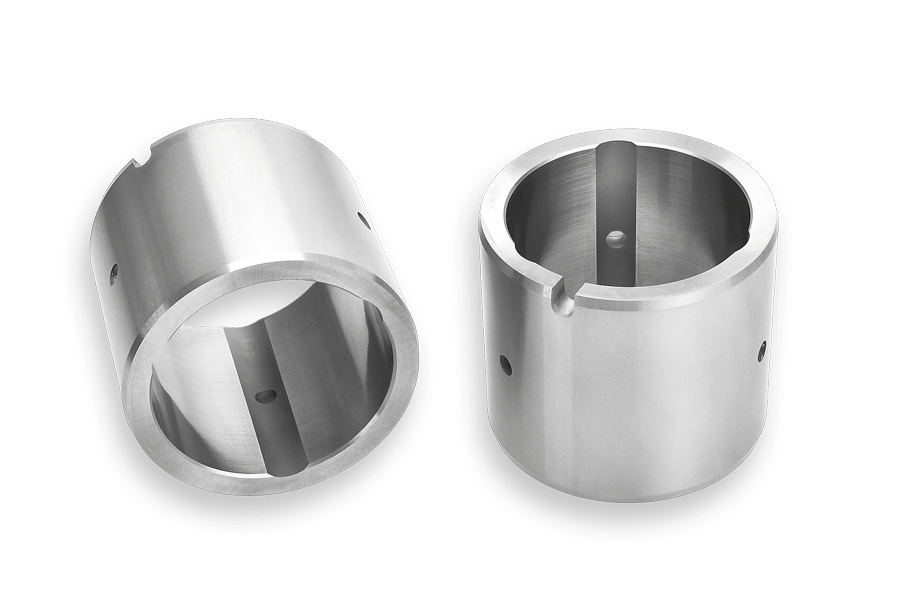

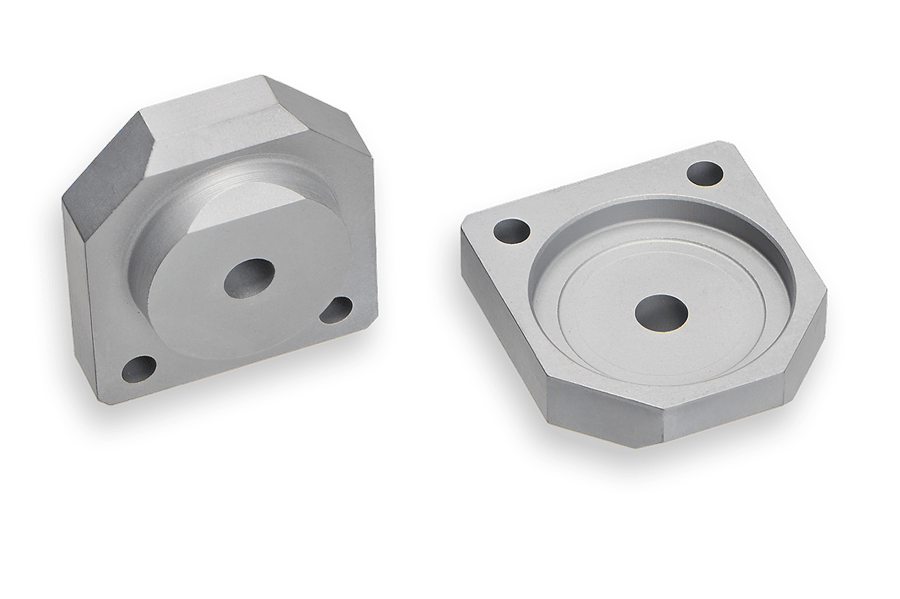

Unser Hartmetall gibt es in jeder Form – als Rohformen oder einsatzfertige Hartmetallteile.

Mit einer Härte von bis zu 2000 HV ist dieser Werkstoff auch den höchsten Anforderungen gewachsen. Aus unserer langjährigen Erfahrung in den unterschiedlichsten Branchen sind Hartmetallsorten mit der exakt richtigen Materialzusammenstellung für verschiedenste Anwendungen hervorgegangen.

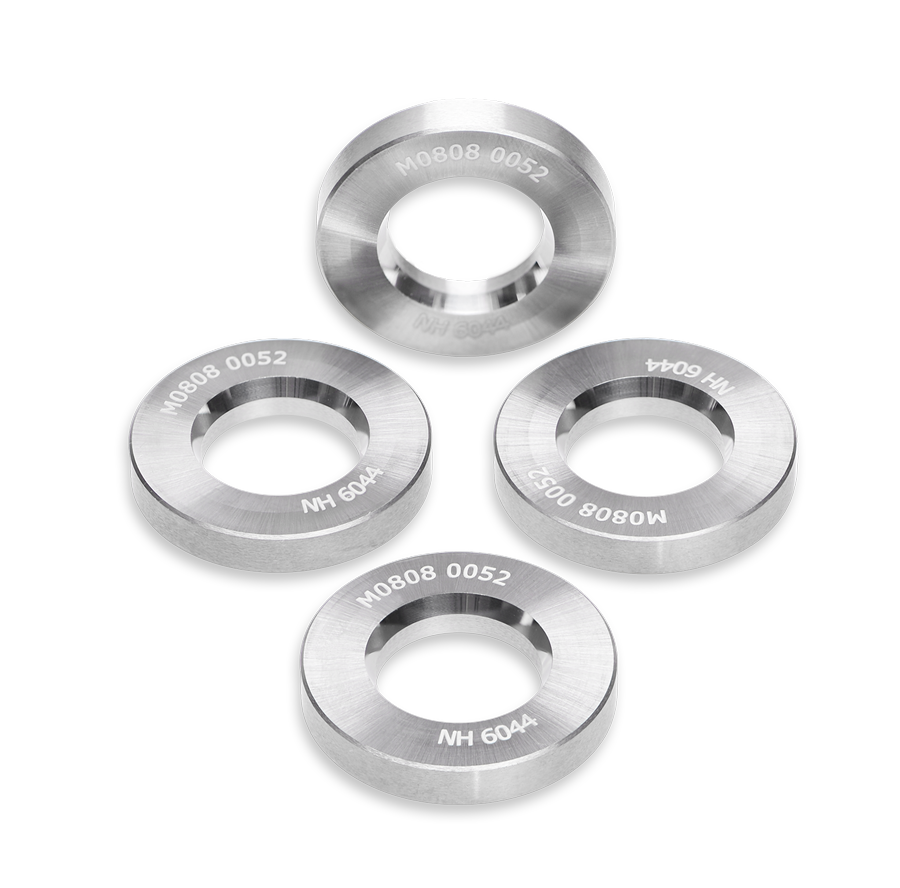

Unsere Hartmetallprodukte finden Anwendung als Führungs- und Bohrbuchsen, Ringe und Ronden, Düsen und Ventilteile, Teile für Mess- und Prüfgeräte, Formen für die Keramik- und Porzellanherstellung, Schneidplatten und Formkörper nach DIN, nach Werksnorm, nach Kundenzeichnung, Zieh- und Tiefziehwerkzeuge, Matrizen, Einsätze für Pulver- und Keramikpresswerkzeuge sowie für die Schrauben- und Mutternherstellung.

Die außerordentlich vielseitige Verwendbarkeit von Hartmetall sichert ihm eine überragende Stellung als Werkstoff in der Verschleiß- und Zerspanungstechnik, im Korrosionsschutz, der Umformtechnik sowie der Gesteins- und Bergbaubearbeitung.

- Lötplatten für einschneidige und mehrschneidige Lötwerkzeuge zur Bearbeitung von Metallen, , Holz und Holzprodukten, Graphit, Kunststoffen und Gestein

- Vollhartmetallwerkzeuge zum Bohren, Drehen, Fräsen, Ausbohren, Trennen und vieles mehr

- Hartmetallstäbe in runder, vierkantiger, rechteckiger oder trapezförmiger Ausführung, sowie in der Herstellung von Sonderwerkzeugen

- Sandstrahldüsen in Standard- und Venturi-Ausführung

- Strahldüsen für das Spritzen und Feinspritzen von Pulvern und Flüssigkeiten

- Presswerkzeuge und Fließpresswerkzeuge für die Herstellung von Keramik, feuerfesten Stoffen und Zementziegeln

- Matrizen und Stempel für das Pressen von Metallpulver

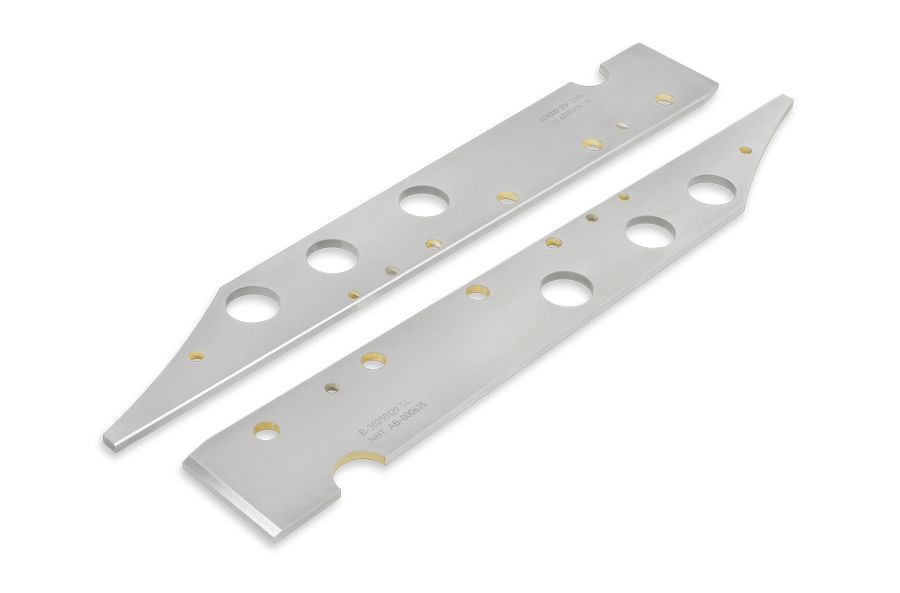

- Rotierende Messer für Papier und gedruckte Schaltungen

- Scherenmesser für Kunststoff und Weißblech

- Gleitringdichtungen

- Ventilschäfte und Ventilsitze

- Draht- und Stangensteuerbuchsen

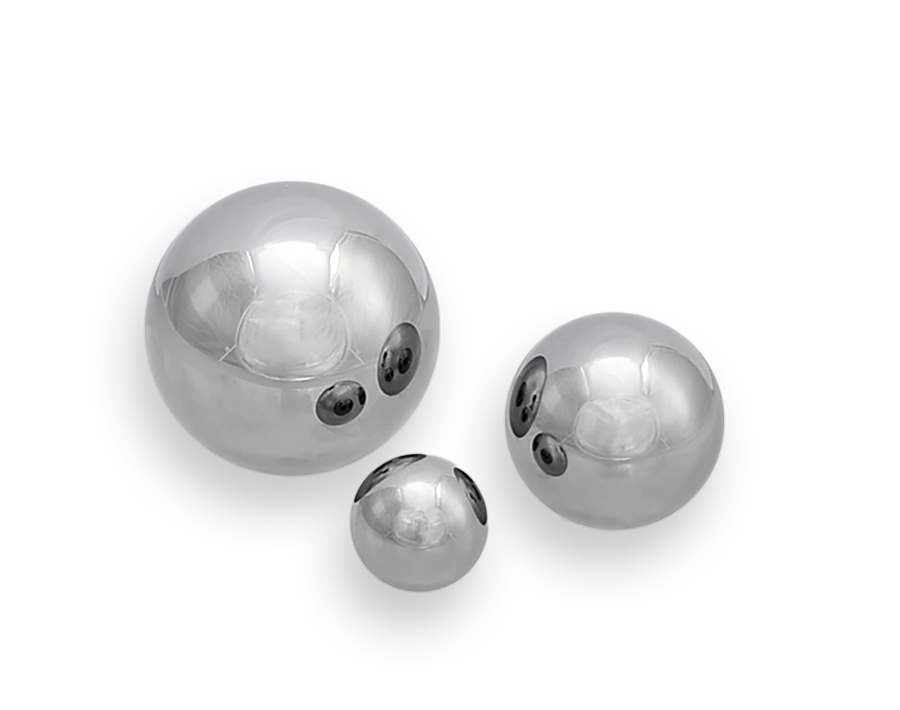

- Mahlkugeln

- Hartmetalle aus korrosionsbeständigen Legierungen für Anwendungen in Chirurgie, Chemie, Landwirtschaft, Lebensmittel- und Erdölindustrie

- Walzen-, Steuer- und Verdrehungsrollen

- Runde und geformte Ziehsteine mit rohgesintertem Bohrungsdurchmesser ab 0,10 mm

- Ziehdorne

- Kerne für Kaltschlagwerkzeuge

- Platten für Drahtscheren

- Matrizen für Muttern

- Abgratmatrizen

- Matrizen und Stempel für das Tiefziehen und Fließpressen von Nichteisenlegierungen

- Teile für Stanzwerkzeuge

- Matrizen und Stempel für Munitionswerkzeuge

- Einsätze für Bohrkronen und Bergbauwerkzeuge aller Art

- Platten für das Trennen und Drehen von Granit, Marmor, Alabaster und Tuffstein

- Platten für Hand- und Maschinenmeißel sowie Kraushämmer

- Platten für Porphyrscheren

- Meißel für Asphaltfräsen

- Glas- und Fliesenschneidrädchen

- Sonderteile für Maschinen zum Zerkleinern von Steinen und Mineralien

Sorgfältige Überwachung der Materialzusammensetzungen und die ständige Entwicklung neuer Fertigungs- und Prüfmethoden sorgen für die hervorragenden chemischen und mechanischen Eigenschaften von Hartmetall.

Eigenschaften

- höchste Verschleißfestigkeit

- hoher flexibler Härtebereich

- hohe Biegebruchfestigkeit

- hoher Elastizitätsmodul und hohe Steifigkeit

- höchste Druckfestigkeit, gute Zähigkeit (sortenabhängig)

- gute Korrosionsbeständigkeit

- ausgezeichnete Wärmeleitfähigkeit

- bessere Warmfestigkeit als bei Stahlwerkstoffen

Einsatzgebiete

- Einsätze, Schnittbuchsen und Stempel für Stanzwerkzeuge

- Formen, Stempel und Matrizen zum Pressen von Metallpulver und Keramikmassen

- Lagerringe, Ventilteile, Strahldüsen für Pulver und Flüssigkeiten

- Zerspanungswerkzeuge aller Art

- Messer für Papier, Kunststoffe, Bleche und gedruckte Schaltungen

- Verschleißteile für höchste Anforderungen im Maschinen- und Werkzeugbau (Befestigung durch Löten, Kleben, Schrauben, Klemmen, Schrumpfen und Eingießen)

Lieferformen

- Formteile nach Zeichnung mit kurzer Lieferzeit

- Profilstäbe

- Röhrchen

- Platten für Drahterosion

- Formteile nach DIN ISO

Mehrbereichs-Hartmetallsorten

Genau abgestimmt auf Ihre individuellen Anforderungen liefern wir Ihnen sämtliche Hartmetallsorten, angefangen bei unseren bewährten Standardsorten über universell einsetzbare Mehrbereichssorten bis hin zu Spezialsorten. Die unterschiedlichen Eigenschaften der einzelnen Sorten werden durch verschiedene Mischungsverhältnisse der Komponenten erzielt. Des Weiteren durch die Auswahl und Kombination der Wolframcarbid-Kornform und -Korngröße sowie durch eine exakt abgestimmte Prozesssteuerung.

Für jede Anforderung hat NHT spezifische Sorten in hervorragender Qualität.

NHT-Feinkornsorten

Die permanent gestiegenen Anforderungen an unser Hartmetall haben wir insbesondere mit unseren hochverdichteten Feinkornsorten GM05F, GM10F, GM15F, GM25F innovativ gelöst.

Die Feinkornsorten bieten Ihnen folgende Vorteile gegenüber den Standardsorten:

- Sehr hohes Zähigkeitsverhalten durch hohe Biegebruchfestigkeit – bis 3900 N/mm²

- Höchste Verschleißbeständigkeit durch hohe Härte – bis HV 2000

- Hohe Kantenstabilität durch sehr feines, dichtes und homogenes Gefüge und daher besonders für Stanz- und Schnittwerkzeuge geeignet.

Kontakt

Haben Sie eine Frage oder eine Anregung? Zögern Sie nicht uns anzusprechen. Hier finden Sie direkt den richtigen Ansprechpartner für Ihr Thema.

Telefon: +49 (0)711 97948 – 0

Werkstoffe

Wolfram, Wolfram-Kupfer, Wolfram-Schwermetall, Molybdän, TZM oder Hartmetall: Unsere Hochleistungswerkstoffe für Ihre individuellen Anforderungen.

Rohlinge ab Lager – schneller Versand

Wir liefern Ihnen über 20.000 Teile in über 200 verschiedenen Profilabmessungen direkt ab Lager.

Sie bestellen und wir versenden noch am Bestelltag!