Wolfram

„Glühend heiß“ ist sein Metier. Einsatzgebiete bis 2900 °C (3173 K) sind möglich. Dadurch erklärt sich der wohl häufigste Einsatz als Glühwendel in Glühbirnen.

Wolfram verkörpert in den physikalischen und chemischen Werten typische Eigenschaften der Refraktärmetalle. Dies sind alle Metalle, deren Schmelzpunkt über dem von Platin (1772 °C) liegt. Wolfram kommt hauptsächlich als Basiswerkstoff in einer Vielzahl von Wolframlegierungen vor, zum Beispiel Wolfram-Lanthanoxid (WL), Wolfram-Schwermetall (WSM) und Wolfram-Kupfer (EROMET). In reiner Form wird es in weit weniger Einsatzgebieten verwendet, beispielsweise für Tiegel in der Beschichtungsindustrie, als Wärmeabschirmung und bei Heizelementen.

Eigenschaften von Wolfram – Wolframlegierungen

Wolfram wird pulvermetallurgisch mit einer Reinheit von mindestens 99,95 % hergestellt.

Chemisch reines Wolfram besitzt hervorragende Eigenschaften, zum Beispiel:

- einen extrem hohen Schmelzpunkt (3420°C) – der höchste von allen Metallen – bei gleichzeitig niedrigem Dampfdruck (bei 2000°C < 4.10-s [Pa])

- einen hohen Elastizitätsmodul

- eine gute Warmfestigkeit bei einem niedrigen thermischen Ausdehnungskoeffizienten

- eine hohe Dichte von 19,3 g/cm³ (bei 20°C)

- gute chemische Beständigkeit gegenüber anorganischen Säuren, Laugen, organischen Säuren, Nichtmetallen, Gläsern ohne Oxidationsmittel, Glasschmelzen und Gasen

- hohe Korrosionsbeständigkeit gegenüber Metallschmelzen

Bearbeitung von Wolfram – Wolframlegierungen

Wolfram ist schwierig zu bearbeiten, es setzt jeder Formgebung und spanabhebenden Bearbeitung einen hohen Widerstand entgegen (hoher Werkzeugverschleiß). Die Bearbeitung von Wolfram und seinen Legierungen wird erleichtert, wenn die Spröd-duktil-Übergangstemperatur beachtet wird. Bei Raumtemperatur ist die Duktilität (Verformungsneigung) sehr gering. Schon kleine Legierungszusätze verschieben die Spröd-duktil-Übergangstemperatur zu niedrigeren Temperaturen. Daher sind grundsätzlich sämtliche Wolframlegierungen besser zu bearbeiten als reines Wolfram.

Die vorteilhafteren Bearbeitungstemperaturen liegen wesentlich über der spröd-duktilen-Übergangstemperatur, die z. B. bei einer Blechdicke von 1 mm bei ca. 200°C und bei einer Blechdicke von 7 mm bei ca. 380°C liegt. Drehen, Fräsen mit Hartmetall, Bohren mit HSS und Schleifen mit Siliziumcarbid sind möglich. Beim Stanzen, Schneiden und Biegen ist die Blechdicke sowie die entsprechende Bearbeitungstemperatur zu beachten. Biegen sollte man möglichst quer zur Walzrichtung (Gefügestruktur in Längsrichtung). Ist dies konstruktiv nicht möglich, dann ist die Bearbeitungstemperatur wesentlich zu erhöhen. Der Biegeradius darf die Blechdicke nicht unterschreiten.

Auch Nieten, Schrauben, Löten und Schweißen sind unter Beachtung bestimmter Regeln möglich. Nieten und Verschrauben ist dem Löten und insbesondere dem Schweißen vorzuziehen, um unnötige Spannungen zu vermeiden. Die Rekristallisationstemperatur ist von wesentlichem Einfluss auf die mechanischen Eigenschaften aller hochschmelzenden Metalle und Metalllegierungen im Hochtemperaturbereich. Über der Rekristallisationstemperatur kommt es zu einer Gefügeumwandlung, die zur Folge hat, dass wesentliche Festigkeitswerte abnehmen und die Bruchneigung erhöht wird. Aus diesem Grund wird eine möglichst hohe Rekristallisationstemperatur angestrebt. Ein hoher Verformungsgrad sowie das gezielte Legieren und Einbringen von Zusatzstoffen erhöht die Rekristallisierungstemperatur wesentlich. Gleichzeitig werden die mechanischen Eigenschaften in Bezug auf das Einsatzgebiet optimiert. Die Bearbeitbarkeit wird wesentlich verbessert.

Anwendungsgebiete:

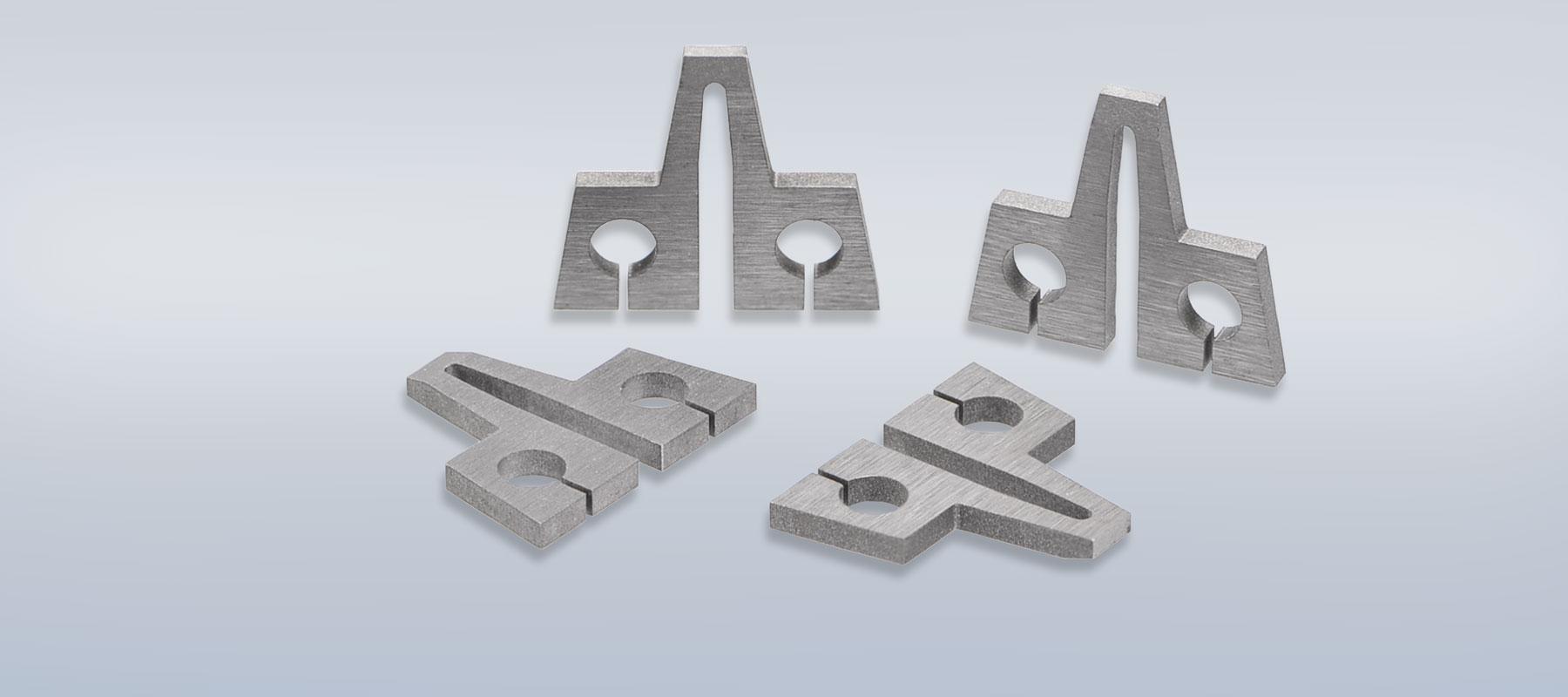

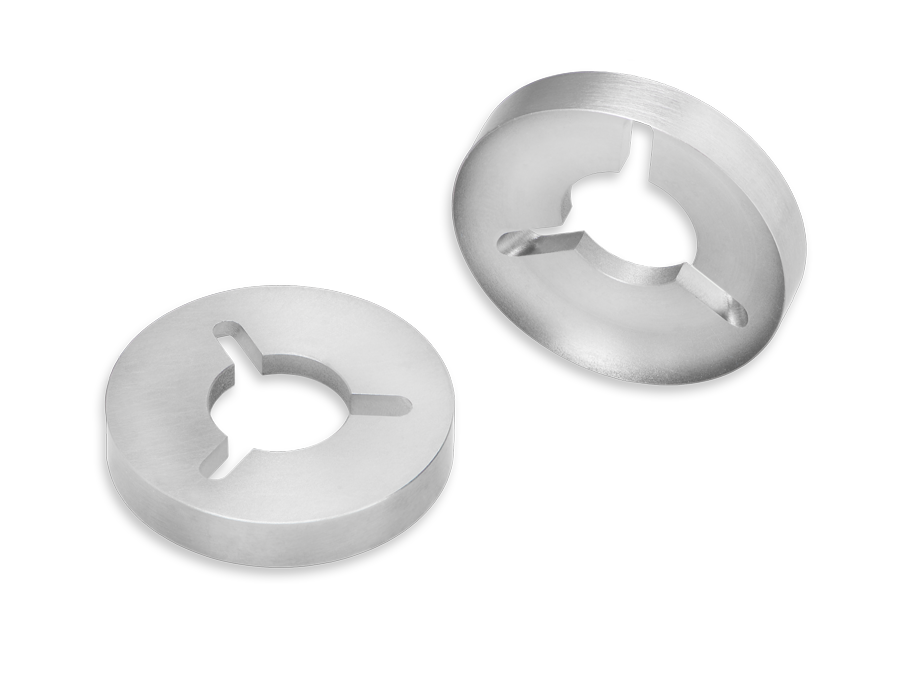

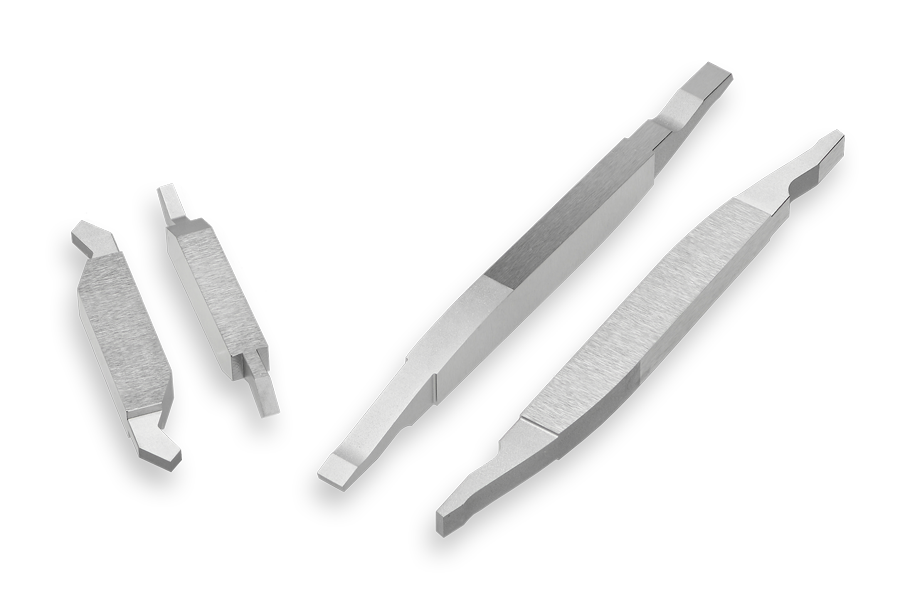

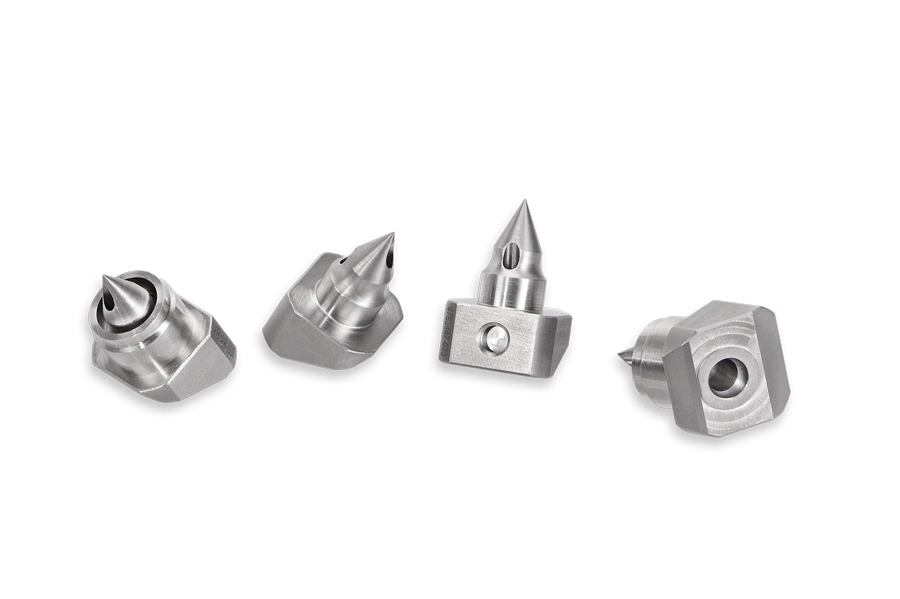

Wenden/Schiffchen für Abdampftechnik, Ronden für Halbleitertechnik, Stromzuführungen und Anoden/Kathoden für Elektronenröhren, Schweißelektroden

Lieferformen:

Kundenspezifische Lösungen nach Zeichnung, Elektroden und Rundstäbe in gebräuchlichen Abmessungen ab Lager, Stäbe, Stifte, Platten, Drähte

Biegetemperatur-Richtwerte

- bei 1 mm Dicke 300 – 400°C

- bei 4 mm Dicke 600 – 700°C

- bei 7 mm Dicke 650 – 800°C

Stanzen- und Schneidtemperatur-

Richtwerte

- bei 1 mm Dicke 400 – 500°C

- bei 4 mm Dicke 850 – 950°C

- bei 7 mm Dicke 950 – 1000°C

Kontakt

Haben Sie eine Frage oder eine Anregung? Zögern Sie nicht uns anzusprechen. Hier finden Sie direkt den richtigen Ansprechpartner für Ihr Thema.

Telefon: +49 (0)711 97948 – 0

Werkstoffe

Wolfram, Wolfram-Kupfer, Wolfram-Schwermetall, Molybdän, TZM oder Hartmetall: Unsere Hochleistungswerkstoffe für Ihre individuellen Anforderungen.

Rohlinge ab Lager – schneller Versand

Wir liefern Ihnen über 20.000 Teile in über 200 verschiedenen Profilabmessungen direkt ab Lager.

Sie bestellen und wir versenden noch am Bestelltag!