Molybdän (Mo)

Unaussprechlich, aber ausgesprochen gut! Wir liefern Molybdän in einer Reinheit von mehr als 99,8 %. Molybdän zählt wie Wolfram zu den hochschmelzenden Refraktärmetallen mit hervorragenden thermophysikalischen, mechanischen und chemischen Eigenschaften.

Molybdän ist gegenüber den meisten Säuren, Laugen und Nichtmetallen beständig. Molybdän ist bei Temperaturen über 100 °C unbeständig in sauerstoffabgebenden und alkalischen Flüssigkeiten. Sehr gut beständig gegenüber Wasserstoff, Stickstoff, Edelgasen, Glas und Metallschmelzen – auch bei sehr hohen Temperaturen. Durch Legieren mit anderen hochschmelzenden Metallen kann das Korrosionsverhalten gegenüber bestimmten Medien noch weiter verbessert werden. Im Vergleich zu Wolfram ist Molybdän schon bei niedriger Temperatur gut verformbar und leichter zu verarbeiten.

Die spröd-duktil-Temperatur beim Umformen ist zu beachten – je dicker der Werkstoff umso höher die Anwärmtemperatur. Oberhalb der spröd-duktil-Temperatur verliert Molybdän seine Sprödigkeit – es kann zuverlässig rißfrei verformt werden. Auch Schneiden, Stanzen und spanabhebende Bearbeitung ist bei richtiger Anwärmtemperatur möglich.

Durch gezielte und präzise gesteuerte Legierungsmaßnahmen erzielen wir Molybdänlegierungen mit weiter optimierten Eigenschaften – genau auf die höchsten Anforderungen im High-Tech-Bereich zugeschnitten.

Zum Beispiel: Molybdän-Lanthan (ML), Titan-Zirkonium-Molybdän (TZM), Molybdän-Kupfer (MoCu), Molybdän-Wolfram (MoW) u.a.

Eigenschaften

- hoher Schmelzpunkt von 2620 °C (2893 K)

- niedriger Dampfdruck

- hoher Elastizitätsmodul

- extrem hohe Warmfestigkeit und Kriechbeständigkeit

- hohe Wärmeleitfähigkeit

- niedriger Ausdehnungskoeffizient

- hervorragende Korrosionsbeständigkeit

- gute Bearbeitbarkeit

Einsatzgebiete

- Rührer in Glas- und Metallschmelzen

- In der Halbleitertechnik als Träger für Leistungselektronik

- Bauteile, Heizeinsätze in Glühofen, Sinteranlagen

- Verdampfertiegel

- Thermoschutzrohre

- Gleitbeschichtungen

- Stromzuführungen in Glühlampen

- Gitterdrähte

- Abblendkappen in Kfz-Leuchten

- Bauteile in der chemischen Industrie

- Katalysatorbauteile

- Wärmesenken

Lieferformen

- Drähte

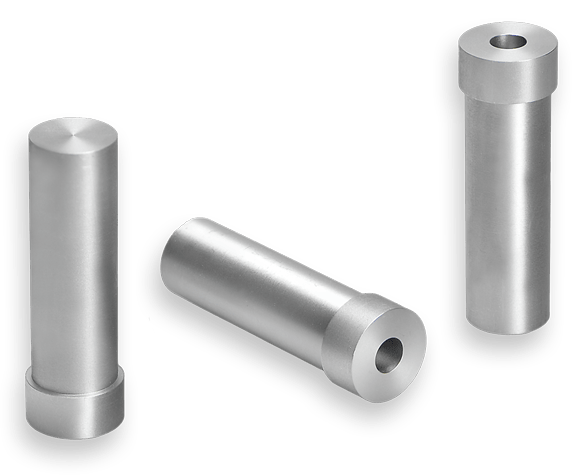

- Rundstäbe

- Profile

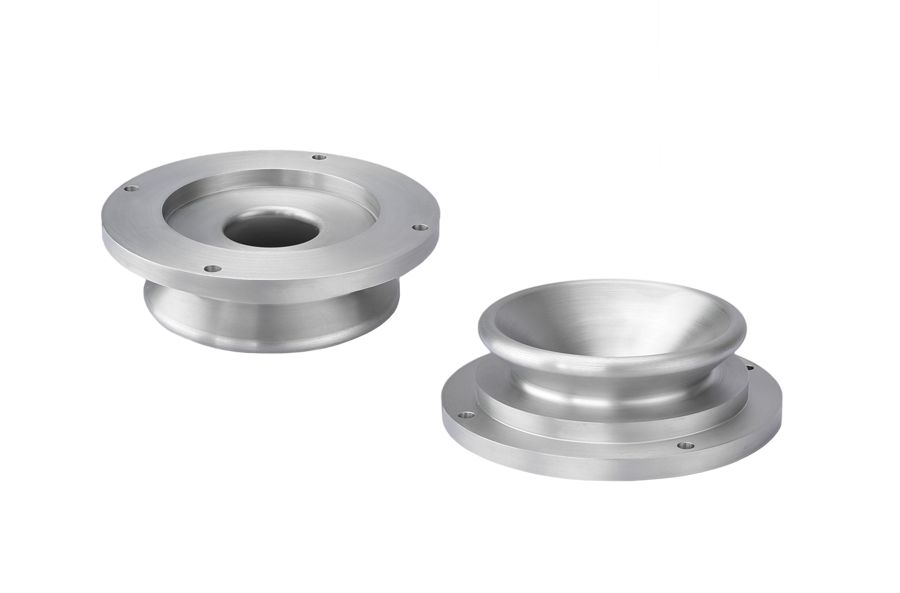

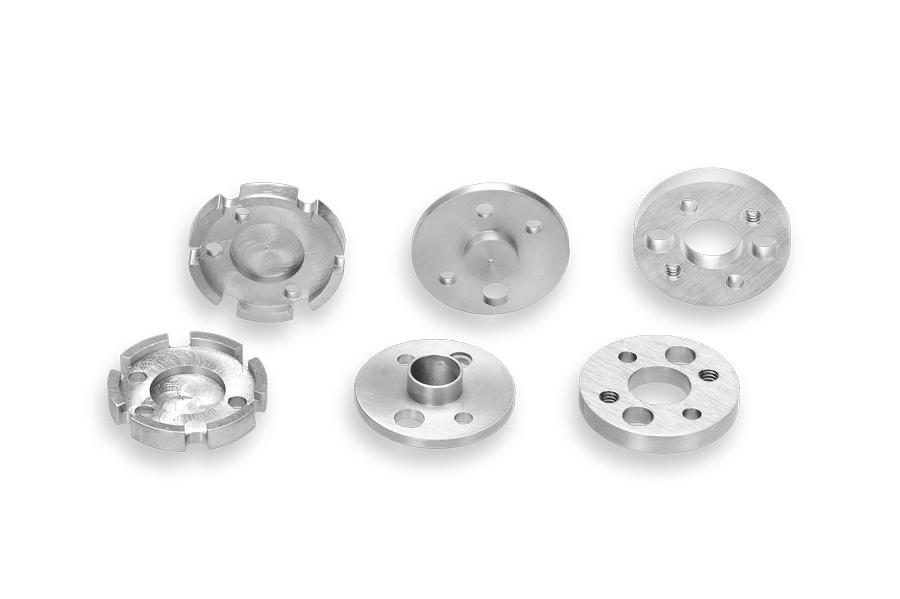

- Formteile nach Zeichnung

Kontakt

Haben Sie eine Frage oder eine Anregung? Zögern Sie nicht uns anzusprechen. Hier finden Sie direkt den richtigen Ansprechpartner für Ihr Thema.

Telefon: +49 (0)711 97948 – 0

Werkstoffe

Wolfram, Wolfram-Kupfer, Wolfram-Schwermetall, Molybdän, TZM oder Hartmetall: Unsere Hochleistungswerkstoffe für Ihre individuellen Anforderungen.

Rohlinge ab Lager – schneller Versand

Wir liefern Ihnen über 20.000 Teile in über 200 verschiedenen Profilabmessungen direkt ab Lager.

Sie bestellen und wir versenden noch am Bestelltag!